Dimelol

-

Posts

16 -

Joined

-

Last visited

Content Type

Profiles

Forum

Gallery

ATV Magazine

Events Calendar

Downloads

Store

Community Map

Posts posted by Dimelol

-

-

57 minutes ago, MarkinAR said:

That's a winch solenoid, if I see 2 in and 2 out correctly. Signal wire that goes to it must be on the hot wire when it should be on a switched ignition wire.

Or the solenoid is just bad and stuck in the closed position.

This unit used to have a wench but it was wrecked and the previous owner had it removed. They told me it had shorted out when the accident happened and fried the "computer", I suppose they meant the CDI box. That's the story I was told anyway. It just seems odd that this would happen out of nowhere. As soon as I try to connect the battery you can hear a very distinct click coming from from it. Sounds like a relay but louder. Should I look into removing it? I have no plans to put a winch back on it.

1 hour ago, Frank Angerano said:Welcome to Quadcrazy, what that part is your showing is the starting relay. If you disconnect the battery wire and hear a click then something is staying on that should not be.

So what I would do is take a test light and take the positive wire off of the battery. Take the test light and connect the clip on the test light and connect it to then battery terminal. Then take the pointer part of the test light and touch the positive battery wire. With the key OFF you should not see the test light on. If you do then there is what’s called a draw on the battery. Could be a bad relay or an aftermarket part that was added to the atv.

Thank you, i'll see about picking up a test light tomorrow.

-

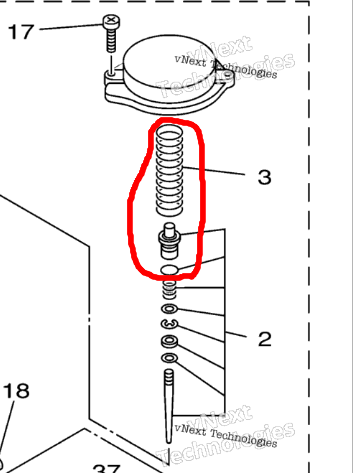

I have been working on my quad for a while trying to get it running right. It seems as if I run into a new issue as soon as I resolve the old one. Anyway, the other day I went to fire up my quad and the battery was completely dead. I knew it was on it's last leg, so I went ahead and swapped it out think it was the issue. After sitting for a couple of days without running the machine at all, the new battery was drained as well, not completely dead like the old one but weak enough not to turn the engine over. When I removed the new battery to put it on the charger I noticed a clicking sound when I was removing the negative connection. After fooling around with it for a bit I tracked down where the sound is coming from (see pic) it was also warm to the touch. I have no idea what this thing or or what purpose it serves but should it be clicking as soon as I connect the battery? Could this be the cause of my battery being drained? Thanks for the help, I'm not the most experienced when it comes to tracking down electrical issues.

-

On 8/19/2019 at 6:42 AM, Frank Angerano said:

That’s a way high rpm for a start up. A cold start rpm should be about 1500 and come down to 800-900. Hopefully your new cheap carb will give you some good indicators as to what’s going on. My guess is the engine will fire right up, idle and run well sitting. Once you go to ride it then you will see how the cheap carbs react and have flat spots on the throttle but maybe you will get lucky.

I installed the new carb today and it idles much better. I am having an issue now where it backfires past a quarter throttle or so. I suppose it is running a little lean now. What you would adjust first to try an remedy that? The needle is easy to access but the fuel air mixture screw is a pain in the as* that requires the carb to be removed all the way. I have it set at 2 turns out.

-

@Frank Angerano @spock58 I put everything back together well enough to start the 4 wheeler to see if it changed anything, no luck. I did record a clip of how it sounds at idle for you guys to see if it gives you any new clues. When I initially start it it hovers at around 2500 rpm for about 30-45 seconds then works it's way down to sounding like this, which is around 1500 rpm (what it should be according to the book). I forgot to record the initial cold start so you won't hear that unfortunately. I figured it couldn't hurt since you guys are experienced with these 4 strokes. I ended up ordering that cheap amazon carb to see if it makes a difference at all. Should be here mid week.

-

8 hours ago, spock58 said:

Well, it has to slide freely but can't have much play at all - the only way to know is to compare it to a new one usually. It's kind of hard to tell with the naked eye. Your slide did appear to move normally and if it was worn down that would allow extra air through making it leaner, right?!

Another thing to watch for is the o-ring on the float valve (needle & seat) - was a new one used when the parts were changed out?

Yeah, i swapped out all of the o-rings and installed a new needle/seat assembly, pressure tested as well. The old one was shot. You are right that would make sense. I'll see how much free play it has tomorrow, It is hard to see in the pictures but it seems like the needle is resting on one side of the nozzle, as if the needle is a little off center. I don't know if that's normal, but it's the only thing I have been able to find that has made me suspicious.

If that doesn't work, I think at this point i am just going to buy this cheap amazon carb and see what happens when i install it. If it solves the issue maybe i can compare it to the OEM one and find out what's going on. Just knowing is worth the 40.00 to me at this point.

-

1

1

-

-

-

8 hours ago, scotty2hotty01 said:

look on amazon for new carb as cheap there.Just a another idea but bought one for a weedwacker for 10.00 delivered work great again.Compression good and gas is new too use highest grade OK I out of ideas but also got to be carb

7 hours ago, Frank Angerano said:Not sure if you want to go down this road but here’s a used one on eBay. It looks in tact and in great condition. Just not sure about your existing carburetor and what’s been done to it.

https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2F%2Fwww.ebay.com%2Fulk%2Fitm%2F362698319020

I appreciate the advice/link. I found one on Amazon during all this mess for like 40.00. Of course it is a knock off, but it has pretty good reviews. I may end up trying that route. All i know is, I wont be happy if i dump like $100 into OEM parts for this one and it not solve the issue. That's why i was hoping that one of these pictures and my re-inspection would find an obvious problem with my current one. I wouldn't mind spending the money then. I may also consider that used one on ebay that you linked, it may need to be rebuilt as well according to the auction though. It's funny that you mention my carb and what may have been done to it. I had to replace most of the hardware due to whoever was in it before me, and the more i think about that the more it concerns me now. I'm no expert obviously, but i'm not a complete idiot either. I was careful about making sure everything i took apart went back together correctly. I appreciate you fellas trying to help me solve this problem.

-

1

1

-

-

22 hours ago, spock58 said:

There should be a few more pieces that go on top of the needle, you have them ok? and did you remove the main jet, needle jet, o-ring, holder, etc. from the carb body? a few more pics would be helpful to see if there's anything missing in there.

16 hours ago, Frank Angerano said:If that engine is not responding to the adjustment on the air/fuel mixture screw then there’s definitely a problem within the carb. I know you’ve been through it all with this carb but somethings off. Especially because it does not shut down when you send it all the way in.

I took a few more pics today but some came out crappy, because I didn't realize my flash was going off. So i apologize for that. I can take more tomorrow if need be. There is a short video as well of the slide operating as well. I figured that might be relevant considering i really don't know how one should operate/sound. Thanks again.

-

2 hours ago, spock58 said:

There should be a few more pieces that go on top of the needle, you have them ok? and did you remove the main jet, needle jet, o-ring, holder, etc. from the carb body? a few more pics would be helpful to see if there's anything missing in there.

Yes, I have the spring and cap with the o ring that are above the spring on the needle. Does that slide look overly worn to you? I'll get you some more detailed pictures of the jet's ect later today. Thanks for the response fellas.

-

2 hours ago, Frank Angerano said:

Is that a new air fuel screw ? If so have you compared it to the old one.

Your engine should sound and act differently as you adjust that screw. Have you tried to set it at 2-1/2 as well as trying 1-3/4?

Everything else looks good as far as I can see.

Yes it is new, along with the o-ring washer and spring. The old one is exactly the same. I have actually been able to put on a glove and turn it as the engine is running (it's a pain in the as* to get to without burning yourself). I have tried both ways and it barely changes anything at all. I have even screwed it all the way in to see if it would kill the engine and it didn't. I have read that can be a symptom of an oversized pilot jet but i have tried both the old one and aftermarket with the same results. They are the exact same size.

-

So today I decided to dig back into the carb for about the 10th time to see if I would notice any mistakes. It has been on my mind the past couple of days. After we spoke i was afraid that I had screwed up when installing the fuel/air mixture screw and it's components. I decided to take a few pictures so you guys could see if you notice any obvious mistakes. Or parts that need to be replaced (mainly the slide assembly). This is the way the fuel/air screw came out. When i installed it all i did was lightly seat it, then back it off 2 turns. Am i missing something here? Can you guys think of any reason why it wouldn't be having much of an effect when adjusted? I also added a pic of the slide/needle assembled so you could see what I was talking about in regards to it being slightly off center. Or am i just nitpicking that? I didn't see any obvious signs of wear on the needle jet or nozzle. I also inspected the diaphragm by holding it up to the sun, and couldn't find any pinholes or anything like that. I dug back into this thing hoping i would find something obvious where i had screwed up, but now i feel just as confused as before.

-

2 hours ago, spock58 said:

Sounds like you may have a problem with the needle & nozzle alright. That would explain the over fueling and also why the adjustment screw doesn't do much. Can you compare the original parts to those replacements? Yamaha didn't offer carb rebuild kits, just individual parts I believe....they're expensive but usually worth it!

I think i am just going to order an OEM needle/nozzle combo along with a new valve throttle (#5) and a new pilot screw set/o-ring/washer . Hopefully that does the trick. You are right, the only rebuilt kits i could find were aftermarket. Yamaha is certainly proud of these parts, but I have already spent enough time screwing around with this thing. I'm ready to be done. I'll let you guys know how things work out. Thank you for leading me down the correct path.

2 hours ago, Frank Angerano said:No problem brother we are here to help. Do some homework on the oem size jets for that carburetor and get an oem rebuild kit and have at it!

You should see an immediate reaction in the engine performance when you adjust the mixture screw. If your not then there’s a problem. That o ring, steel waster and spring assembly has to go in right on that mixture screw.

Study the carb diagram and make sure everything is correct.

Any Questions ask away.

I'm going to order an OEM set and make sure it is correct. Thank you for the help!

-

1

1

-

-

8 hours ago, spock58 said:

Unless you see a misfire using a spark tester I doubt that there's an ignition issue - still sounds carb related. One thing that comes to mind is the pilot screw, is the little o-ring & spring properly in place? Usually this results in a lean condition at low rpm which makes for rough idle & bogging or hesitation. Since your symptoms indicate richness (ie. black plug) there could be wear on the needle in the slide, was this replaced already? You also have to replace the piece that it slides into, at the top of the needle jet. This is a likely reason why it over fuels and is really noticed at the closed throttle position. I will see if I can show a parts diagram of this. You should try needle set #2 & nozzle #16. Pilot screw o-ring is #9

https://www.ronniesmailorder.com/oemparts/a/yam/50038fb7f870021f60a0ca5f/carburetor

It's funny that you mention that because now i remember that during all of this troubleshooting, there was one odd thing that I found. When i tried to adjust the fuel/air mixture screw on the bottom of the carb it had basically no effect on how the engine ran either way. From my understanding if it is screwed all the way in the engine shouldn't be able to continue running correct? Because i did try screwing it all the way in to see if it would kill the engine and it wouldn't. Could that be due to the O-Ring you are speaking of being not properly installed? I brought it up on another forum and they told me it was an over sized pilot jet causing it (if i remember correctly), so i swapped it but nothing changed. I haven't really thought about that since, until you mentioned that about the pilot screw. Also, I did replace the needle and nozzle but they are not OEM. I noticed the old one that I removed, and the new one i installed didn't seem to line up perfectly with the main nozzle, it seemed a little off center. Could that be causing it not to seal properly? I'm beginning to second guess myself on everything now lol. Oh one other thing, at idle the exhaust is rather strong smelling. So you are thinking i have both a rich and lean condition happening at the same time from different sources basically? I appreciate the help.

9 hours ago, Frank Angerano said:Good point, I’m with you on the carburetor.

@Dimelol it really does sound like it’s a carburetor issue. I would I go back and check it again and make sure all the proper oem jet sizes are in the carb, needle is set as per spec on the proper clip location and that air fuel screw is installed right and also in good condition. Sounds repetitive but worth the effort.

I would still check the voltage on the battery while it’s running to make sure your getting the 14 volts at the battery and make sure your regulator is within spec just for sh*** and giggles.

You guys have convinced me to revisit the carburetor. I'll be sure to check the battery as well to be safe. I appreciate the response.

-

TLDR: Could these ignition components being out of spec cause a rough or choppy condition at idle? I know the factory specs are there for a reason, but i just want to make sure i'm not barking up the wrong tree here. My main concern is the Rotor rotation direction sensing coil since it seems to be the furthest out of spec. Any insight would be greatly appreciated. Thank you!

Spark plug cap resistance: 10 kΩ at 20 °C (68 °F)

My Reading: 8.90 kΩPrimary coil resistance: 0.18 ~ 0.28 Ω at 20 °C (68 °F)

My Reading: Fluctuated between 0.4 - 0.5 ΩSecondary coil resistance: 6.32 ~ 9.48 kΩ at 20 °C (68 °F)

Reading was within the specified range.Pickup coil resistance: 459 ~ 561 Ω at 20 °C (68 °F)

Reading was within specified range.Rotor rotation direction sensing coil resistance: 0.085 ~ 0.105 Ω at 20 °C (68 °F)

My reading was 0.3 Ω -

I have a 2003 Kodiak 450 that i purchased a while back with around 300 hours on it. It has never ran right from the beginning. Initially i thought it was just a carburetor issue because it was all clogged up from sitting for months. It has been cleaned, rebuilt, and taken off probably about 10 times troubleshooting this problem. I have quadruple checked everything including float height ect and it is set correctly, the jets are also brand new, needle and seat have been pressure tested as well. So after all of that I am convinced that the carburetor is not the culprit. I have an issue where the idle is very choppy, almost as if it is misfiring with a rich condition on top of that. I can use a brand new plug and run the machine for just a few minutes and it will be a dry and and coated in black carbon build up. The exhaust also has a strong smell at idle. I had trouble restarting it when hot for a while, but i adjusted the valves and it seemed to solve that issue. They were both way out of tolerance (tight). The weird thing is, outside of idle it seems to run pretty well.

So with all that being said I have ruled out the carb/valves/compression and moved on to the ignition and this is where i have a few questions about factory specifications. I guess the main question I have is, how strict are these tolerances? And could them being off by this amount cause the issue I am having? Do all three of these parts really need to be replaced? I would like to know before I spend the money on these new parts, and it not fix my problem. Below I will list what the specs were in the service manual along with the reading i got. This is my first experience testing ignition components. I just found it odd that all 3 are out of spec according to the service manual.

Spark plug cap resistance: 10 kΩ at 20 °C (68 °F)

My Reading: 8.90 kΩPrimary coil resistance: 0.18 ~ 0.28 Ω at 20 °C (68 °F)

My Reading: Fluctuated between 0.4 - 0.5 ΩSecondary coil resistance: 6.32 ~ 9.48 kΩ at 20 °C (68 °F)

Reading was within the specified range.Pickup coil resistance: 459 ~ 561 Ω at 20 °C (68 °F)

Reading was within specified range.Rotor rotation direction sensing coil resistance: 0.085 ~ 0.105 Ω at 20 °C (68 °F)

My reading was 0.3 Ω

Battery drain while sitting 03 Yamaha Kodiak 450

in Yamaha ATV Forum

Posted

I'll double check tomorrow, but I am faily certain that it is just the 2 normal leads plus 1 extra positive lead, and a tiny green wire that is connected to positive as well.