JustRandy

Members-

Posts

751 -

Joined

-

Last visited

-

Days Won

53

Content Type

Profiles

Forum

Gallery

ATV Magazine

Events Calendar

Downloads

Store

Community Map

Everything posted by JustRandy

-

Ah ok. I can tell you know what you're doing, but I'd never guess 66 for being so tech savvy posting pics n stuff. I guess you're the type determined to know a bit about everything. Good trait If you have a head you want to sell I've been meaning to buy one to throw on the shelf just in case I spin another bearing or something. Just ain't had the ambition to search ebay yet.

-

I use this Can't find it anymore though. I bought cases of it in 2017 from amazon so I'm stocked for a while. Walmart used to have it for $2/qt, but that's ancient history now.

-

Looks like you are correct. Although some JASO oils do contain the modifiers. https://www.oilspecifications.org/jaso.php So you want JASO MA oil.

-

From that I can tell you've either done a lot of reading or a lot of living lol What are your plans? Are you going to fix n flip them? Or build one up into something? Or something in between? The head is the same as the 250S Quadsport so there are lots of cams to choose from. Likewise with the piston. You could even get crazy with a KZ1000 piston and resleeve.

-

The pic with the blue goop oozing out the inspection plug for the cam is very concerning. It's pretty common for that goop to find its way onto the cam bearing with disastrous results. I use as little goop as possible on the valve cover and I've seen some guys who don't use any. The first thing you're going to want to check on those machines is the regulators. It's a known issue and if they aren't bad, they will be soon. I'd pop them off and have a look at the epoxy on the back. I'd also be checking the intake valve lash. If there is no lash then the intake valve and seat are toast. Reach out if you have questions. There isn't much about those machines that I didn't know at one time lol

-

That isn't true at all. The additive package is the reason they make special oil for atvs and motorcycles. And I've noticed from my own experience that using regular automotive engine oil immediately resulted in a clutch that didn't grab as well. Auto oil is too slippery for wet clutches. I can't comment on that specific oil but it seems to me unless you're romping on your motorcycles (street bikes?) maybe the atv requires more friction which could give you a false sense of security regarding the oil you're using in your motorcycles. The differences in friction requirements between machines is something to to think about. But once the wrong oil is used there is no going back, so even if the oil is the cause of the slipping you'd still have to replace (or clean very well) the clutch disks. You could try to wash the inside of the engine with kerosene then refill with proper oil, but who knows if that would work. Every wet clutch is engineered to work in tandem with a lubricant with specific coefficients of friction. That's why every automatic transmission requires a certain oil. Another cause of clutch slipping is low oil, so I'd first check the oil level before proceeding. The way to differentiate the clutch pack from the centrifugal clutch is to ride at a constant speed then suddenly gun it. If it starts slipping then it's the clutch pack. Another way is to gun it right after shifting into a higher gear and before letting off the shifter.

-

Yep it's the lightest full size quad ever made. Mine is right around 300lbs wet. I can bunny hop it with the engine off in the garage. I guess the bad part of the goki starter is it adds a bit of weight. Another unique feature is the stroke (67mm) is longer than the bore (66mm). I don't know of any other quad that is under-square. On top of that, 67mm is a long stroke for any quad in its class. It's longer than the 350 Warrior. The torque and light weight make for a unique riding experience. They will also handle a lot of abuse so long as the chain stays on and the rod doesn't break. Here's one with a turbo:

-

Based on what little I can see of the swingarm it's either 87 or 88. In 85 and 86 they had a cam type chain adjuster. In 87 they changed to bolts and slots. If it has a starter then it's a 230E, but it doesn't look like one. It could have a Goki starter which were popular add-ons back in the 80s. If so that may be worth more than the quad. Post a pic of the mag cover and I could say more. Honestly, you have a lot of work ahead of you. It looks like the swingarm bearings are toast, which is a common problem. Another common problem is the chain coming off and smashing the magneto cover. Those run about $200 if you can find them anymore. If you have a Goki you definitely don't want to smash that. Also the wrist pin is rather weak which lets the piston flop around leading to smoking. In 1990 they up graded from 16mm pin to 17mm, but they only made those engines 2 years and are really hard to find. A 230 that doesn't smoke is pretty rare. You're going to have to replace practically everything from a-arm bushings and swingarm bearings to magneto coils and maybe valves. The amount of work involved isn't going to be worth it unless you just like to work and spend money. That quad was one of the first and Suzuki cleaned up many of the problems in 1990. If you could post what you have of the VIN and some more pics of the side and swingarm I could say more. Also what is your goal with the quad? Edit. I'm sorry. I meant to say 1989 and 1990 is when Suzuki cleaned up the problems with the 230. They did it to compete with Honda's 250X.

-

Your "help" is the worst thing that can happen to people. You should have told the OP not to lap his valves or at least warn him of the consequences of doing so, like I did. You let him make an uninformed decision and now he's stuck. I can't be here all the time to warn everyone about your bad advice because I do have a life outside of this.

-

That's the only thing you've been right about. Congrats! Pop the cork on some fine scotch in celebration.

-

Do you oil pistons when you install them or do you install them dry? It's another controversial topic that's been debated for years. I want to know what you do so I can do the opposite.

-

Your track record is abysmal. You were wrong about regulators, wrong about carbs, wrong about lithium batteries, and now you're wrong about valves. You haven't provided any substantiation for any of your claims. All you do is cry like a kid who didn't get his way. There is no way to avoid it looking like that drawing. Reputable shops don't lap valves. It's an IQ test: if they lap valves, find someone else.

-

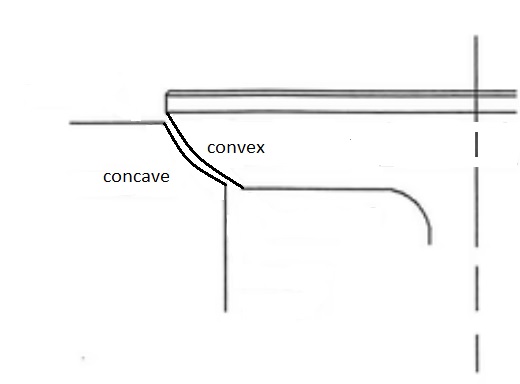

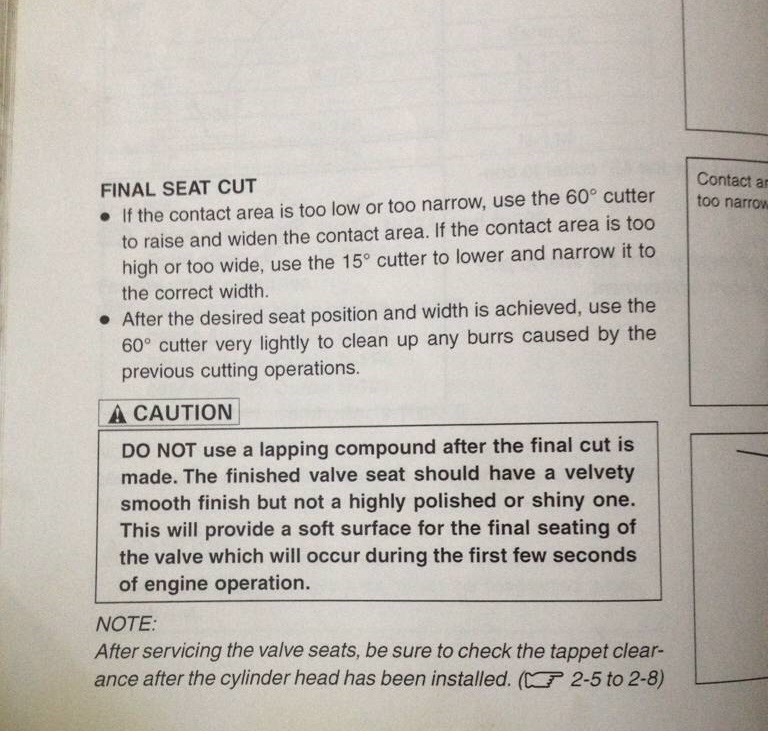

He is saying lapping results in valves and seats looking like this: In addition to not sealing properly, curved surfaces do not allow air to flow as well as flat, which is why seats are ground to angles like this: So, lapping removes hardness layer on valve, impregnates surfaces with grit, and results in curved surfaces instead of angles. Nothing good about it.

-

Given that you would install some of those worn valves I posted I can't believe you have ever done a valve job. And if you have, that's even more scary. On vehicles I take heads to a machine shop to be milled and do the valves, but I do the porting myself. On atvs I cut new seats with a Neway cutter and do not have valve problems anymore. No one will ever go near my machines with grinding compound.

-

If it were my site I'd be more concerned that I had two guys masquerading as wise old mechanics who are evidently nothing of the kind because dispensation of bad advice only makes the site look bad in the end. If you don't understand how valves wear, nor have ever seen one, then what could you know? If you put a new valve in an old seat, it's going to look like the pics I posted, regardless if it was lapped or not. Lapping only accelerates the process. The fact that you haven't discovered that says it all.

-

To the OP: If you lapped a new valve to an old seat, here is what is going to happen: A year or so down the road you will notice it's a bit hard to start when cold. You'll assume it's a dirty carb or something and not think much about it. Then the hard cold starting will get worse until eventually you're back on here asking for help. One way or another you will get to adjusting the valve lash and you will think that was the problem and it was just routine maintenance that fixed it. No big deal right? But then the hard starting comes back as the valves continue to wear. You'll readjust the valves again and again. Eventually you'll be setting the lash every week, then every day just to get it to start. And if you keep going like that, you'll notice a severe loss of power because each time you make a lash adjustment you are changing the cam profile. In the end, if you keep going, the valve will pop right through the seat, forcing you to finally do it right. Or you'll just abandon the quad and buy something else. Here's a pic from a guy who posted on here before: And here's how I knew: I've seen it a lot. And I'm not even a professional mechanic.

-

Which manual? One is DRZ, another is Deere, and the other is unknown. I found them online in other threads debating the merits of lapping. They were all the correct valves. Most of them are 230s (32mm valve) or 250s and 300 king (33 mm valve). At least one is a 220 bayou. Plus I have some heads with the valves still in them that are probably just as worn, including a bayou head. That's what happens to new valves installed in old seats, whether lapped or not. The wear you see is from the friction between the valve surface and the seat, not the lapping. Lapping just removes the hardness of the valve allowing it to wear faster, as the service manual said. Holy cow! And you call yourself a mechanic!?! Every valve has a gouge worn out of it. Hopefully you are not indicative of most Kiwi mechanics.

-

In order to learn you first must be able to admit you're wrong. Unfortunately, you don't seem to have that power. The real tragedy here are those you presume to "help". You should be ashamed guiding so many people so wrong. Those are YOUR failures because those valves were according to YOUR method.

-

So, I went through my service manuals and none recommend lapping valves. And I found some that explicitly recommend against it. Lapping compound is only used in valve jobs as a replacement for paint to illustrate how the valve is seating in order to know where to make further cuts. And here is my own experience with lapping: The number of times lapping a new valve to an old seat failed: So once again you've placed yourself at odds with manufacturers of tools, service manuals, and outcomes in reality. You are so consistently wrong on everything that if you and I ever agree on something I will have to reconsider my position.

-

Your advice is to lap valves, yes? If so, then I've followed your advice for years and had 100% failure. Only when I stopped following what you recommend did I stop having failures. Not hard to understand. Wisdom comes from making lots of mistakes,,,, but you have to learn from your mistakes.

-

Only when following the advice that you recommend. And I followed it diligently for years. I always found excuses to explain the failures rather than blaming what you and others recommend. Problems that occur years down the road can always be explained some other way. Maybe it's just a fluke. Maybe I did something wrong. Maybe the valve was faulty, Maybe the air filter didn't do a good job. Yada yada. One thing I can guarantee: if you lap a new valve into an old seat it will fail. I've done it dozens of times and each time I had to replace the valve again within 2 years. Only when I started cutting seats did I get any longevity. Disregarding your advice is the only thing that worked for me. That's becoming a consistent trend on here.

-

Yep, I did that. I listened to those guys and I habitually lapped valves before finally realizing that 100% of the valves I lapped needed replaced within 2 years. There was never once that lapping successfully replaced a seat cutting. For a while I chalked it up to bad air cleaners, but after switching to the best air filters and still needing to replace valves I eventually narrowed it down to lapping new valves to old seats. If you lap a valve to a seat that has just been cut then you might get away with it without catastrophic consequences. It's still a bad idea, but you might not have to replace the valve. If you lap a new valve to an old seat there is 100% chance the valve will need replaced in a couple years. I have a whole box of bad valves I could show as examples, some from the 220 bayou. Valve lapping is specious: it sounds good, but doesn't work in practice. I lived it.

-

Valve heads are carefully machined to a precise angle and hardened. If you grind on them in any way you are altering the carefully machined angle and you are removing a layer of hardness. Once the hardness is gone the valve wears down quickly in my experience. I'd only recommend a very very light lapping in very rare circumstances. The idea of a valve job is to make the angle of the seat match the angle of the new valve, that way both angles will be 45 degrees exactly. If you lap a new valve to an old seat then neither angle will be 45 degrees. Lap your valves if you want them to look like these down the road: Also, Neway Manufacturing who makes the seat cutters does not recommend lapping after cutting. https://www.newaymfg.com/cutters This page provides the rationale for why not: https://motorcycleproject.com/text/valve_jobs_done_right.html You don't want round edges on your valves because it impedes flow. A 3-angle job is supposed to be angles, not curves. So, there is rarely ever a situation where lapping is a good idea. Rounded corners, loss of hardness, grit impregnated in the valve metal are always bad ideas.

-

That suggests a loose timing chain. I used to have one of those quads and I had to weld a couple nuts to the tensioner to take up the slack. Yep, two nuts stacked on top of each other to make the pusher long enough. I may have done some milling on the jug to increase compression which would have made the chain too long, but I think it was pretty long to begin with. When you set the valve timing be sure the chain is tight or your setting will be off. Assuming a valve isn't sticking and you have the lash set correctly then the only other likely possibility is the valve timing is wrong, which could be caused by a loose chain. Or maybe you're lining up the wrong marks or your lash setting isn't letting the valve close. A more unlikely possibility is the cam is wrong or the sprocket isn't attached to the cam properly which is throwing off your timing. Also, I wouldn't lap the valves because it wears the hardness off and then your valve won't be able to hold a lash setting for long. The right thing to do (in light of all the work you're putting into it) is to cut new seats and install new valves made in Japan. Your seats already have the wrong angle because they wore along with the valves so if you just slap in new valves the angles won't match and your valves will wear out quickly. There is really no way around cutting new seats if you want to do it right.

-

1990 Suzuki Quadrunner 250 LT-4WD - Mixture and Valve specs

JustRandy replied to BenderIsGreat's topic in Suzuki ATV Forum

I've done that a long time ago lol I'd probably weld more metal on then heat it to remove hardness then cut new threads with a die. Or hire a machinist to do it. I've welded more metal on cams lobes and polished it up then did the same to the rockers. Because weld is so hard it will last longer than stock. I used some differential gear paint to make sure the cam was riding flat on the rocker. I'm kinda proud of that