Leaderboard

Popular Content

Showing content with the highest reputation on 02/27/2019 in all areas

-

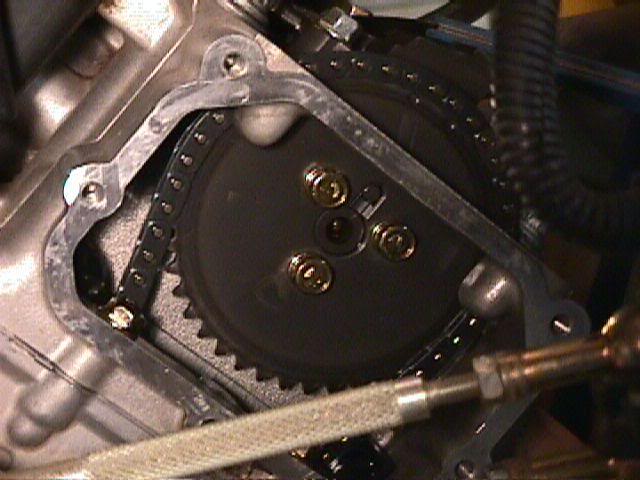

I've never done this before but after reading a few thread I decided to check my valves for the first time and to my surprise it was much easier than I thought. My bike is a 2005 Sp 500 HO. I first pulled the seat and the right side panel off, and that's it! It wasn't too bad to get at. Next I pulled the spark plug out and removed both the head cover ( 8-8mm bolts) [ATTACH]1021[/ATTACH] then the side cam cover (5-8mm bolts). [ATTACH]1023[/ATTACH] Also remove the plug in the recoil cover (14mm bolt) to see the timming marks. [ATTACH]1022[/ATTACH] Next I turned the engine over with the pull cord untill it was at TDC of the compression stroke. The best was to tell that your at TDC of the compression stroke is to rotate the engine until the timing marks are parallel to rocker cover gasket surface. The cam sprocket locating pin will be facing upward directly in line with the crankshaft to camshaft center line. Now fine adjust by looking into the timing hole in the recoil cover and line up the upside down "T" on the flywheel into the center of the hole. [ATTACH]1023[/ATTACH] Now using a feeler gauge, slide the .006" (.15mm)blade between the top of the valve and the bottom of the adjuster and adjust accordingly [ATTACH]1024[/ATTACH] [ATTACH]1025[/ATTACH] To adjust, Loosen the locknut (10mm) and check clearance with a feeler guage. Clearance should be .006" (.15mm) for both, intake and exhaust valves. Turn the adjuster with a stubby flat blade screwdriver untill the proper clearance is achieved then tighten the locknut (5.8-7.2 ft. lbs) while holding the adjuster in place with the screwdriver. Re-check the clearance with the feeler guage one last time and re-assemble the covers (72 in.lbs) and plugs. The only thing that i noticed was that I had to clean and silicone the side cam cover other than that I found the whole process rather simple. I'd give it a 4 out of 10 on the skill level scale. I hope this helps! Thanks Rich1 point

-

ARCTIC CAT BRANDED SIDE-BY-SIDES AND ATVS ARE COMING BACK Passion can change people. Change minds. And in the end, it can take us back to where our family has been all along. Because Arctic Cat fans and powersports enthusiasts demanded it, the Arctic Cat® name will be returning to ATVs and Side-by-Sides in 2019. With a legacy of innovation, performance and fun, our legendary lineup of ATVs, side-by-sides and snowmobiles are built to take you anywhere you want to go — from carving up mountain snow on a Mountain Cat Alpha One in British Columbia, to flying over the dunes in Glamis in a Wildcat™ XX. And these high-performance vehicles are still made proudly in Thief River Falls, Minnesota. https://www.arcticcat.com/the-cat-is-back/1 point

-

Ok the reason I’m asking: 1. I’m wondering if there is a problem with the vacuum where as soon as you hook the air box up the vacuum lines are drawing all the air from the air box starving the air flow into tye carburetor. Why? No clue! Just wondering if that’s what’s going on. May sound stupid but you never know Try to move the needle on the carburetor and see how that goes. Make sure you remember where the clip was on the needle before you move it. If that’s not the fix then disconnect all hoses going to the air box, reconnect to the carb and try to run the bike and see what happens. Side note. That clip and spring set up in the carburetor can be tedious. Parts can fly off and never to be found again. Work in an area that will prevent that from happening.1 point

-

That saw I bought from HF about 5 years ago. The compound slide version. That saw was good for what I needed it for however whenever I used it the electric motor gave off a burning smell that resembled marajuana. So my customers would look at me funny and I had to explain that it’s the saw. I had to turn the saw on to show them. I still have the saw and use it for only demo work now since I’ve upgraded to a better saw but that one did the job and yes it still smells. It’s a smell from the electric brushes but man it was a weird smell.1 point

-

1 point

-

I just got a 2003 arctic cat 400 and I'm having a time finding where the cdi box plug is located. Guy said he took it off and forgot where it was located. Made no sense to me but hey what do I know. Any help would be appreciated.1 point

-

I like your setup! not familiar with Ryobi myself but if it holds up for 30 days, I bet you get plenty of solid use 💪1 point

-

Ryobi is stepping there game up. That saw will do what you need it to do! It’s not a contractors preference because it will not stand up to the every day use! But if your buying it to do the standard home repair and occasional chop job then it will do just fine! Nice choice and I’m sure it will meet your needs. I’m not a fan of harbor freight but I like that other people are enjoying the tools they buy. I believe and when I say I believe you get what you pay for I mean it. I like a good name that backs there product. And will take it right back and give you a new one if there is ever a failure! That’s just me, I do a ton of work and put all of my tools through the ringer. I like to push a tool to its limit.1 point

-

Check the kill switch, left handlebar, red switch, that would prevent the fuel pump from pressurizing. Check ignition fuse (IGN on the fuse block) it could have popped and you would still have dash and headlights, but the pump won't pressurize. On these machines, the start circuit would only prevent the starter from engaging, the fuel pump will still pressurize. Arctic cat machines allow you to start the machine in gear only if the brake is engaged. There is a relay called "start in gear" but I don't think this is his problem. It is either the kill switch or something in the IGN circuit. Since this is an EFI machine, battery condition is very important, battery may appear to be OK, but only a load test could verify that. Mike1 point

-

It sounds like a lean issue with both quads. Is the stock air filter in place ? Some quads lean out and don't want to run right without the air filter . Check to make sure there's nothing restricting the fuel flow to the carb. Also check to see if a small piece of crud has gotten into the carb inlet and resstricting fuel flow past the float needle . The new carb you bought might not be calibrated properly for your machine. Check the clip on the main throttle needle. You may need to move it down towards the needle tip to make it open more under throttle. Check is the idle air screw. It may be adjusted a little too lean. That would let it idle but when you go to open the throttle the mixture goes a bit to lean and it stumbles. All these lean burn symptoms would be more pronounced when the motor is warm. Those are about all I can think of to suggest checking .. Good luck and Happy New Year .1 point

-

Magnets at flywheel mine just went this fall, should have been a recall but it happens 10 orso years later, thats my two cents. Yooper1 point

-

Check that the gearshift lever, on the left side of the motor is moving normally when you operate the shift handle. If it is, take the belt off, put it in gear and try to turn the driven clutch by hand. If it turns easily, it's either not going in gear or the input/driven clutch shaft is broken. I've never seen one of these shafts break but that doesn't mean it can't happen. Neither drive shaft is moving when you rev it in gear, correct? Does it sound like it's going in gear when you shift it into gear?1 point

-

Could be the carb sucked in some of the dust and clogged the jets. I would remove and clean the carb. Mike1 point

-

Heres my findings during the valve adjusting process. The two exhaust valves were just less than .004" and the intake valves were tight with no gap causing pressure on the valve it's self. Everything is now adjusted to .006". So I took the bike out for a little run today and I noticed a few things. First the "Pros" The first thing was how easy the bike started, next was how the idle had smoothed out. The idle dosn't fluxuate as much anymore. Throttle responce is a tad better too. Now the only "Con" if you can call it a "Con". There is now a valve train noise that was not there before I did the adjustment. I guess the slight ticking sound is normal, also good for the Cam and the general performance of the engine. Only a "Con" because of the noise.1 point

-

0 points

This leaderboard is set to New York/GMT-04:00

.thumb.jpg.72d9d16cf3fa4a494d09f57c860272c4.jpg)