-

Posts

3,925 -

Joined

-

Last visited

-

Days Won

208

Content Type

Profiles

Forum

Gallery

ATV Magazine

Events Calendar

Downloads

Store

Community Map

Everything posted by Frank Angerano

-

That thing looks like a beast! Extended swing arm ? Love the cooler on a dune bike!

-

Starting problem 2004 Suzuki Twin Peaks

Frank Angerano replied to Jeff Miller's topic in Suzuki ATV Forum

Based on that photo i feel you can get a regular three claw puller on that flywheel. Auto parts place will have that. Just be careful that you don't damage the end of the shaft with the puller. -

2000 Kawasaki Bayou 300 Occasional Misfire

Frank Angerano replied to Lance Workman's topic in Kawasaki ATV Forum

Your welcome! -

2012 Suzuki kingquad 400ASI not going into top gear?

Frank Angerano replied to Belmontie's topic in Suzuki ATV Forum

Great pic! Looks like a Suzuki commercial or advertising pic. Just curious, are you on the throttle while shifting or off the throttle? Does the shifter not even come up or hard to come up? Reason I'm asking is it may just be a clutch adjustment or maybe the belt ? -

Great pic. Ive always wanted to do a sand run.

-

2000 Kawasaki Bayou 300 Occasional Misfire

Frank Angerano replied to Lance Workman's topic in Kawasaki ATV Forum

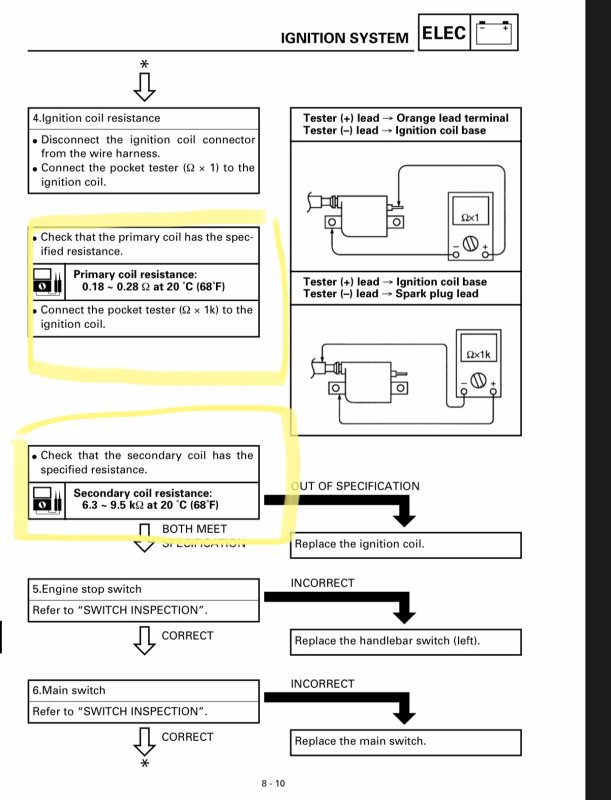

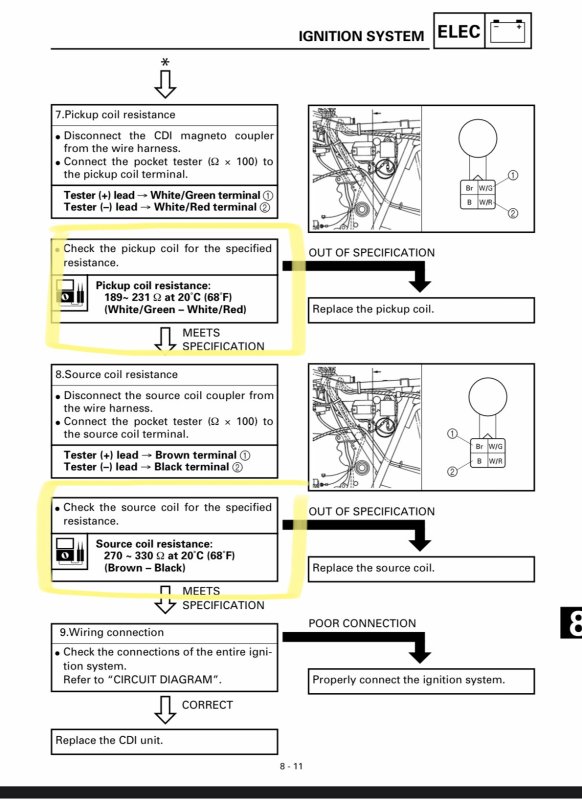

My apologies. That was from the 220. Here are the 300 numbers. I pulled these out for you. Should be good with these numbers. -

Anyone getting stuff done at home?

Frank Angerano replied to Frank Angerano's topic in General Talk - Anything Goes!

Very cool. "Around the wall" layout. Much better way to explain it. Nice work mike! -

2000 Kawasaki Bayou 300 Occasional Misfire

Frank Angerano replied to Lance Workman's topic in Kawasaki ATV Forum

-

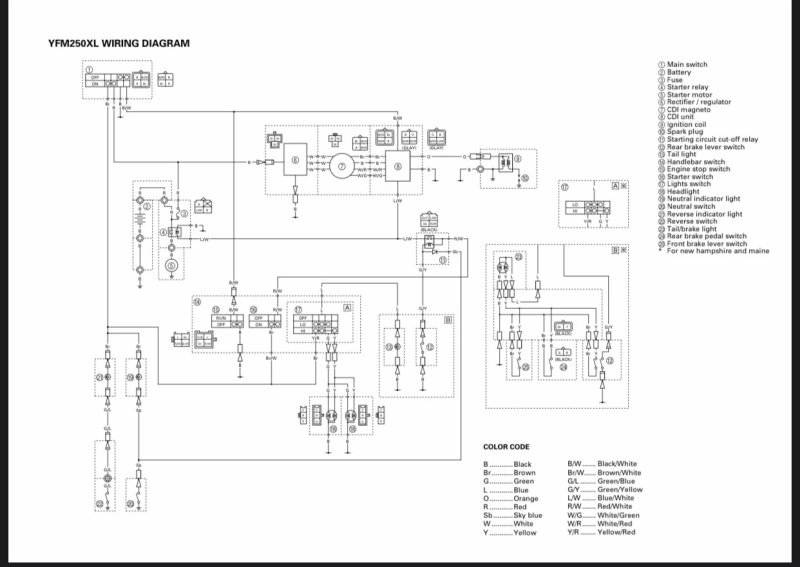

no spark Yamaha YMF 250 Bear Tracker No Spark

Frank Angerano replied to Timothy Doerr, Jr's topic in Yamaha ATV Forum

10-4- 21 replies

-

- bear tracker

- yamaha

-

(and 1 more)

Tagged with:

-

Probably going to be valve stem seals or a piston and rings. (Maybe both) bit definitely going to need a compression test to see what's happening. Are you adding oil to keep up with the level ? Also what's the oil level? (Not over filled) is what I'm getting after. Lastly does the oil smell like gas?

-

2000 Kawasaki Bayou 300 Occasional Misfire

Frank Angerano replied to Lance Workman's topic in Kawasaki ATV Forum

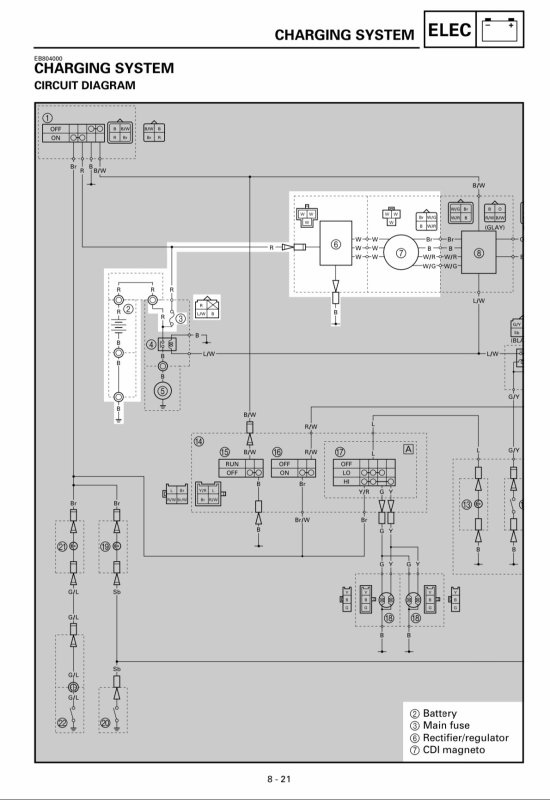

Your looking on the wrong page. It should show you a stator coil page with a number reading from (example) 0.30 to 0.65 as a range and if you tested and it came back as 0.55 then its within range. These numbers are only for example Now the pick up coil should show you the same type of table but a much higher number like 189 to 330 for instance. Try and locate those pages. The page your showing me looks like a regulator/rectifier table. -

2000 Kawasaki Bayou 300 Occasional Misfire

Frank Angerano replied to Lance Workman's topic in Kawasaki ATV Forum

Neutral safety switch. They should run down into the left side of the engine? -

2000 Kawasaki Bayou 300 Occasional Misfire

Frank Angerano replied to Lance Workman's topic in Kawasaki ATV Forum

Ok so the first pic is your stator wires. 3 of them. Each one is called a phase and they come from the engine side. Not on the harness side. Take a tester and set it to ohms, test the wires (each phase to phase). Call them A,B,C. So put the test leads on each of the wires one in A and touch B and check your reading and then touch C and see your readings and then B and C. Your numbers between all of the phases should be about the same and that number should be within the range listed in the manual. Test each of the phases to ground also. Phase A one test lead the other to ground on the frame. You should not get a reading. Do that with B and C as well. Any readings from a phase to ground is a bad stator coil. The second pic should be your pick up coil. Two wires. Put your test leads on the two wires in that plug and check your readings. The number should be within the range shown in the manual. -

Starting problem 2004 Suzuki Twin Peaks

Frank Angerano replied to Jeff Miller's topic in Suzuki ATV Forum

I ordered mine from Amazon. Took two days to show up. -

no spark Yamaha YMF 250 Bear Tracker No Spark

Frank Angerano replied to Timothy Doerr, Jr's topic in Yamaha ATV Forum

- 21 replies

-

- bear tracker

- yamaha

-

(and 1 more)

Tagged with:

-

2000 Kawasaki Bayou 300 Occasional Misfire

Frank Angerano replied to Lance Workman's topic in Kawasaki ATV Forum

Hey @Lance Workman welcome to Quadcrazy. Do some testing and check the readings on the stator and pick up coil to see where they are. Do you have the acceptable ranges listed in the manual ? I would also check your readings on the rectifier/regulator and the ignition coil feeding the spark plug. Also while the engine is running wiggle the wires going into the stator cover to see if any worn areas of the wire are possibly rubbing agains the engine causing a momentary short. Continue to wiggle wires along the frame as well as it could be a short somewhere along the harness. Lastly does this happen during wet weather or going through puddles or any particular time like after the engine gets hot? -

2000 Yamaha Bear Tracker idle/starting issue

Frank Angerano replied to cameron walton's topic in Yamaha ATV Forum

Yep. Last test is each phase of the stator wires to ground. Tester on continuity, you should not get any reading. Open circuit is what your looking for.- 23 replies

-

- bear tracker

- idle

-

(and 1 more)

Tagged with:

-

Anyone getting stuff done at home?

Frank Angerano replied to Frank Angerano's topic in General Talk - Anything Goes!

Definitely does @Ajmboy! Years ago i used to smoke pot. Loved it and would love to do sh** like that. Now i look at it and think nope! -

no spark Yamaha YMF 250 Bear Tracker No Spark

Frank Angerano replied to Timothy Doerr, Jr's topic in Yamaha ATV Forum

Good for you. If i get some time i will help out.- 21 replies

-

- bear tracker

- yamaha

-

(and 1 more)

Tagged with:

-

no spark Yamaha YMF 250 Bear Tracker No Spark

Frank Angerano replied to Timothy Doerr, Jr's topic in Yamaha ATV Forum

Your very welcome. thats what makes Quadcrazy unique! Pay it forward to the next member!- 21 replies

-

- bear tracker

- yamaha

-

(and 1 more)

Tagged with:

-

Starting problem 2004 Suzuki Twin Peaks

Frank Angerano replied to Jeff Miller's topic in Suzuki ATV Forum

Post a pic of the side view of the engine so i can see the flywheel. -

2000 Yamaha Bear Tracker idle/starting issue

Frank Angerano replied to cameron walton's topic in Yamaha ATV Forum

Stator 0.45-0.55 phase to phase Pick up coil 189-231 Source coil 270-330- 23 replies

-

- bear tracker

- idle

-

(and 1 more)

Tagged with:

-

Starting problem 2004 Suzuki Twin Peaks

Frank Angerano replied to Jeff Miller's topic in Suzuki ATV Forum

That to me seems like the engine kicked back almost like a backfire. The engine cover should stop the floating of gears when its installed so i don't think that's a problem. I am going to say at this point your going to have to definitely check your timing to see thats all in order. Im in the city. You? -

no spark Yamaha YMF 250 Bear Tracker No Spark

Frank Angerano replied to Timothy Doerr, Jr's topic in Yamaha ATV Forum

Here are some screen shots of numbers your looking for. If your not clear on testing please feel free to ask. I will be on the road for about an hour. Check back later to see how you made out.- 21 replies

-

- bear tracker

- yamaha

-

(and 1 more)

Tagged with:

-

no spark Yamaha YMF 250 Bear Tracker No Spark

Frank Angerano replied to Timothy Doerr, Jr's topic in Yamaha ATV Forum

I agree with you @Timothy Doerr, Jr but you have to tackle one thing at a time. At least thats how i operate. For instance i would locate and get the ignition ordered and while im waiting for that do some testing and research and start solving other problems. So having said that you should be able to download the manual from our downloads section and lets look at the ignition wires we can safely put together and see what happens and what comes to life. I will help you along with that. @MarkinAR is absolutely correct on checking continuity on the existing wiring and he will jump in as well on the wiring. This is not going to be as difficult as it sounds. I find it easier to print the diagram out and highlight the different wires with colors to make life easier.- 21 replies

-

- bear tracker

- yamaha

-

(and 1 more)

Tagged with: