-

Posts

1,044 -

Joined

-

Last visited

-

Days Won

197

Content Type

Profiles

Forum

Gallery

ATV Magazine

Events Calendar

Downloads

Store

Community Map

Everything posted by davefrombc

-

kawasaki kef300a electrical

davefrombc replied to Rusty Quadrunner's topic in General ATV Discussion

Make sure the quad is in neutral, check there is power to the ignition switch, then the process of elimination starts at the battery positive and ground and works through the circuit. You can quick check the starter by running 12 v directly to the terminal momentarily to see if it spins over ( assuming you at least have power to the lights and indicators) Usual problems are bad grounds, broken wires and corroded terminals, or defective relays. Check in that order. Electrical problems can sometimes be a real PIA to trace out . -

If it is doing it without a load on it ( being driven) it could be a restriction in the fuel getting to the carb .Level dropping to the point it is running lean and then quits.. after a few seconds , enough fuel reaches the float bowl for it to run again for a short period.. If it is when being ridden, it might be a component in the ignition system breaking down as it heats up. Those are my two stab in the dark guesses.

-

Try rocking it a bit while trying to take it out of park.. It may be binding a bit if the quad is on a slight slope. I have a friend with a Kymco 700 and he has had to do that occasionally.

-

94 Timberwolf Rear Brake no adjustment left.. Drums maxed out

davefrombc replied to Jim's topic in Yamaha ATV Forum

Just do a search on "94 timberwolf rear brake drum" .. There are a number of suppliers that come up, with several offering free shipping in the US. Prices vary a lot between suppliers . -

Arctic Cat Prowler 2007 Service manual View File Service manual for the 2007 Arctic Cat Prowler Submitter davefrombc Submitted 07/19/2017 Category Arctic Cat ATV

-

-

Searched for your manual and came up with this site. http://www.mymowerparts.com/pdf/ It has service manuals for all sorts of equipment , including the Arctic Cat 700. I'll add that manual to the list in QC's downloads folder.

-

1995 Yamaha 350 big bear Solenoid click

davefrombc replied to Scoopeddad's topic in Yamaha ATV Forum

It could be a corroded connection, the solenoid or the starter motor.. A quick way to check the starter motor is to run 12 volts directly to the motor terminal. If the motor spins over you know it is ok and you need to look elsewhere in the circuit. -

View File 1985-90 Suzuki LT230 / 250 service manual Service manual for the Suzuki LT230 / LT250 1985-90 LT230GE LT-F230G LT230S LT250S Submitter davefrombc Submitted 07/12/2017 Category Suzuki ATV

-

-

Free Suzuki ATV Service and Repair Manuals

davefrombc replied to oxidized_black's topic in Suzuki ATV Forum

Here is the link to download the service manual for the Suzuki LT230 /LT 250 service manual -

Search on 2001 yamaha bit bear 400 cdi. There are a bunch of hits on e-bay, and other sites .. Here is an American company listing one .. Expensive ..... http://www.cheapcycleparts.com/oemparts/a/yam/50038e92f870021f60a0c2fb/electrical-1

-

At the top of the page you'll see the heading "Browse" . Mouse over it and choose "Downloads" . In that folder you will see on the right a list of the manuals available. The Honda service manuals can be found under "Other" Here is the link to the file in that folder you are looking for. It covers both the 2 wheel drive TRX300 as well as the 4x4 TRX300FW models.

-

1994 Kawasaki Bayou 300 ignition problem.

davefrombc replied to JamesD's topic in Kawasaki ATV Forum

Any one of them could be the problem. That's where it comes to tracing circuits and wires until the problem is found . I can't point to any one thing and say "That's it" . All I can do is suggest places to look . -

Shoulda looked at a picture o your axle before I posted LOL.... I see your quad has an IRS rather than a solid axle like my old Honda. I just watched a video on removing the axle and see it is just slid into the differential housing so it is the hub that keeps everything in place. It likely is the right one and play should be pretty much gone with everything buttoned up. My only experience with an axle similar to that is the drive axles on my car .. They are held in the same way , and there is a little play withing the cv joint on them that I originally thought was a problem but it is a function of the joints .

-

Is it possible the axle has a short spline one one end and a long on the other and it has been installed the wrong way around?.. There should be no end play in the axle if it is installed correctly and the proper axle for the installation .

-

Today is our day to celebrate being the best nation on Earth.. Canada Day .. July 1st ... to those celebrating our countries birthdays ( Canada and the U.S.of A. ) this weekend, I say have a very Happy and Safe holiday weekend. To those that will not be online Tuesday.. Have a very Happy and Safe July 4th.

-

My first guess would be a faulty accelerator pump (hole in diaphragm ?) but also look for an air leak, or lean run from a partially plugged jet. Try adjusting the air bleed screw. It may have turned out on its own.

-

1994 Kawasaki Bayou 300 ignition problem.

davefrombc replied to JamesD's topic in Kawasaki ATV Forum

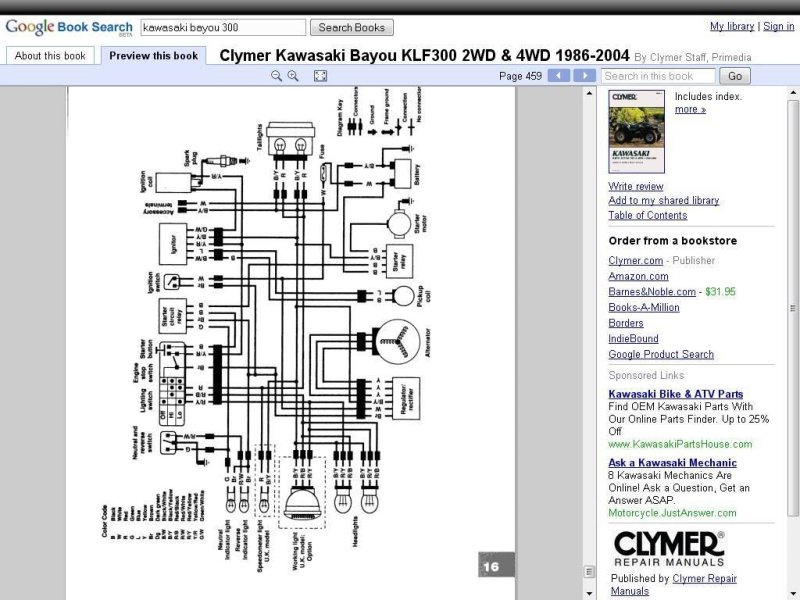

Note there is a connection from the starter relay to the CDI box to deliver power from the relay to the CDI when the starter is running . When the starter is not running the CDI gets its power from the ignition circuit. -

1994 Kawasaki Bayou 300 ignition problem.

davefrombc replied to JamesD's topic in Kawasaki ATV Forum

Since it you have replaced everything in the spark circuit , it is time to start checking again to make sure none of the wires and connections are broken or corroded. Here is the wiring diagram for your quad. -

1994 Kawasaki Bayou 300 ignition problem.

davefrombc replied to JamesD's topic in Kawasaki ATV Forum

The stator and the pick up coil or just the stator ? The stator and pickup coil together produce the power and pulse to fire the CDI and coil. The stator produces the electricity to run the machine and all its components and accessories. The pickup coil creates a pulse to trigger the CDI box at the proper point in the cycle to fire the spark coil. -

The clear tube was used to show the fuel level in the float bowl. it is not part of the installation .. To use it , the screw would be backed out to allow fuel to fill the hose .. Since liquids will seek an equilibrium level, it is an easy way to see just where the fuel level in the float bowl is when chasing carb problems . That screw would normally shut off fuel to the line except when draining the float bowl or using that trick to see the level the floats are actually holding in the carb... It could be low causing fuel problems, or with the fuel tank above the carb, it could show that the float needle valve is leaking allowing the catb to flood and leak. If the needle valve is in tight and fuel is still leaking from that line , I would say the the needle seat is damaged and allowing the leak. With that screwed in all the way there should be no fuel getting into that line .

-

I searched on your carb and it appears it is a float bowl drain hose (if I got the right carb in my search) there should be a screw to close the drain. If it is right , close the screw. Looks like it is there to easily drain any water out of the carb if you get some contaminated gas. https://www.google.ca/search?q=bayou+300++carb+adjustment&tbm=isch&tbo=u&source=univ&sa=X&ved=0ahUKEwjskrywpNrUAhUH32MKHeiKARYQsAQIXQ&biw=1696&bih=1015#imgrc=UhZ7gJl4FLWlWM:

-

Did you check to see if the driven clutch is free to open up?.. If it is sticking it can prevent the drive clutch from closing all the way. You can get tachs that work on a optical system. Put a reflective mark on a rotating pulley , clutch or whatever and the hand held optical tach reads the reflections as pulses to calculate rpm Search on "hand held optical tachometer" or "laser photo tachometer"

-

I searched on the revving problem and found suggestions that the slide could be in backward or the crank seals could be leaking several suggested the crank seals were the most likely culprits. Here's where I found the discussion https://atvconnection.com/forums/suzuki/348745-1991-lt250r-reving-its-own.html